e mërkurë, 29 shtator 2010

e diel, 28 mars 2010

e mërkurë, 19 gusht 2009

e martë, 19 shkurt 2008

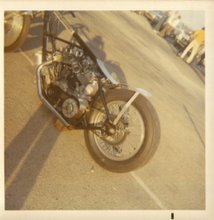

My Early Days of Fighting the Snake Wobbles

By Grandaddy Joe Smith, All Rights Reserved

In the early days (1969) when I fell down at Irwindale Raceway in the lights due to a lock to lock wobble it was on the first Chassis I built. When the wobble started it was a slow kind of snake wobbling and then all of a sudden it was lock to lock. At the time I didn’t know the first thing about Rake and Trail and when I built the chassis I gave it a little more than stock rake. When I built the next chassis I bought a book on Motorcycle Frames and read about Rake and Trail, now that I knew what they mean I could understand the mistake I made on the first chassis.

The next chassis I built had 7 ½ inches of trail, the rake was 43 degrees. At the time it was considered a space age designed but it still had those little snake wobbles. I went to Laid law’s Harley Davidson and borrowed the devise they used to spin the front wheel doing a wheel balance. I put the bike on a block of wood under the motor with just enough height for the front tire to clear the ground, spun the wheel as fast as the machine would spin it and turned the handlebars left and right and let go and the forks would come back to center, I tried every way I could to make it go into a wobble but it always returned to center. I spun it up again and went to the rear and gave the slick a slight slap on the sidewall and the thing almost fell off the block in a lock to lock wobble. I tighten the steering dampener like always thinking that would take care of it, spun it up again, gave the slick another little slap on the sidewall and it was worse. I took hold of the slick at the very back and moved the tire side to side slowly it would get that snake wobble. I started loosing the dampener until it was completely loose and lost the snake wobble. From then on the dampener was always loose; I eventually took it out of the neck.

It was right after that I was at the Harley Factory asking for a new truck and the President at the time was AMF, he came from Chrysler and while he went about getting me a truck he had someone take me to a meeting in the Engineer Department to get me out of his office. There were some pretty big guys sitting around this table including Dick O’Brian (racing Dept.). There were a lot of things being discussed and it came around to the Police Bike and its wobble problems. They discussed it for quite awhile and finally O’Brian looked at me and asks what I thought about the problem. He took me by surprise, but I knew he was trying to put me on the spot because some of my money came out of the Racing Department (most was from Advertisement) and he didn’t like it. So being the entertainer I am I stood up and begin talking.. “You Gentlemen know that the reason the Police Bike has a problem is simply because of the weight on the rear because of the Radio Boxes. They’re made out of steel, why don’t you make them out of Fiber Glass like your Saddle Bags and take that Dampener off the front forks and maybe your wobble problems will be on the way to being solved. Guess what?

The time I spent working in a Sailplane Company I learned some things that could be applied to building a chassis. The biggest thing I ever learned about curing wobbles came from there. They have there “Bench Racing” and one night I stayed to see what they talked about. During the conversation one of them ask me what kind of problems I face in the Drag Race world. I mention speed wobbles. He laughed a little and said we have our wobble problems too but it’s in the tail. He explained that when the Sailplane developed a tail wobble they try to correct it but they couldn’t move the stick the right direction fast enough to stop it, they just make it worse. They came up with the ideal of letting go of the stick and the tail stopped its wobble. He said he understood I couldn’t let go of the handlebars but maybe if you put even pressure forward with both hands it might work. On my singles even with the dampener out it had the snake wobbles occasionally but would stop on its own. When the next snake wobble started; I push forward with even pressure with both hands and the snake stop sooner.

I felt that what started the wobbles was the slick would get hooked up at growth and did what I called “begin to walk on the side walls” which cause the rear section to make the chassis pivot on the bottom bearing of the fork stem and if the dampener was tight enough it would work its way to the forks instead of staying there on the bearing.

The year I went to Bonneville I put those small dampener’s on that went from the frame to the forks and every run I made I had to shut down because of wobbles that started every time I shift gears. I took them off and It solved my wobble problems.

Every good run I made with my Double Engine Top Fuel Harley would get that snake wobble every time I shifted into high gear and I stopped everyone with that “push forward with even pressure with both hands”.

I’M NOT SAYING THAT YOU SHOULD DEPEND ON THAT WORKING ON YOUR BIKE. I’M JUST SAYING THAT’S HOW I LEARNED SOME IMPORTANT THINGS ABOUT BUILDING A CHASSIS IN THE EARLY DAYS. BUT IF YOU GET THE OLD SNAKE, GIVE IT A TRY...

e hënë, 23 korrik 2007

From Kick Start to Bump Start to Rollers To Tow Start To The Electric Starter

When I first started drag racing I started my motor with the kick starter on the transmission. It was always hard to start because of different engine timing, smaller batteries and ignition distributor locked in position. We also went through a period of what they called bump start, that's where one or two people push you by hand and you rise up on the rear pegs and throw your weight toward the seat and let out the clutch.

When I first started drag racing I started my motor with the kick starter on the transmission. It was always hard to start because of different engine timing, smaller batteries and ignition distributor locked in position. We also went through a period of what they called bump start, that's where one or two people push you by hand and you rise up on the rear pegs and throw your weight toward the seat and let out the clutch.When my motor got bigger in cubic inches and piston compression went up it was impossible to kick start or bump start any longer. Now I have to hold on to the door handle of the truck with my right hand and the truck pulls me up to speed (about 35 MPH) I let go and let out the clutch and the motor starts and is ready to go about the task of making a run down the drag strip. This was done at all drag strips and it was called the fire up road.

A lot of years went by using the fire up road and the NHRA decided it was getting to dangerous because some times the Dragsters and Funny Cars fired there Engines right in front of the spectator stands and it was taking up to much time with so many entries, as Drag Racing is a popular sport and has many Spectators at NHRA Events.

As the years progressed the Cars with Blowers were already changing to hand held starters to start there engines, this worked well on cars with blowers because of the very low Compression Ratio they ran.

The Rollers were the next advancement in starting Dragsters and Funny Cars and the bikes were allowed to use these rollers. They were positioned right behind the starting line and speeded up the races. I always like the rollers; it brought a lot of excitement right there to the starting line, for the racers and the spectators.

And then we got the big announcement from NHRA. The rollers will be done away with and all Entries must have there own starters. Most of the Dragsters, Funny Cars and other Automotive had already been making the switch. That left all Motorcycles that relied on something to start there motors with a new situation. It took awhile for someone to make one that worked, the motorcycles compression was so high that the starters they first tried were having a hard time doing the job, but with some gear reduction they came up with a good starter.

I took my double to an Automotive Shop that made starters for the cars. I ask him if he could make me a starter that would work on my bike. He gave me the parts I would have to install on the bike for the starter, said come back next week and pick up your starter.

The following week I returned and he was going to show me how to use it. He had one battery hooked to the starter, hooked it on the parts I installed per his instructions, hit the starter button and smoke came from the start. He said we are going to need more battery. He fixes the starter with another starter motor and hooked it to three batteries, connected it to the double, hit the start button and smoke came from the starter. By this point he's getting frustrated. Ask me what the compression was on the motors, 10.4 to 1. Well no wonder it won't work. Give me a couple weeks and I will figure something out, it will be different than any thing out there, but I don't know quite what it will be like yet.

It was actually a month before he called me. When I got there, he pointed over to this thing on the floor and said there's your starter. It was the drive motor out of an Electric Golf Cart. I went over and looked down; it was almost as big as one of the motors in the bike. It had a handle on it, I picked it up and said WOW, what does this thing weight, 90 pounds he says with a big grin on his face. I told him there was no way my Family could handle that on the starting line, its way too heavy. He told me it's that or no starter and he wasn't sure it would do the trick until we try it, you will have to build something with wheels on it to put the starter in and roll it right up to the mounting bracket.

We started with one battery with the Spark Plugs out of the motors, it turned over great. Put the plugs back in and tried it again, it went up to the compression stroke and stopped, he let off the switch right away so not to burn the thing up. We spent most of the day trying different things, ended up with four batteries and he felt that wasn't enough. We tried the batteries in different wiring series and found the best was one big battery.

I did build a special little cart with wheels for the starter, it worked out better than I thought, and it also took place of the block of wood I used to hold up the bike in the pits. It was hard for the family to put back into the truck, I usually had it all hooked up and ready to start and one of the family disconnected it and it took two of them to put it back in the truck. I did have to use five pretty large truck batteries that I built a special compartment for in the back of the truck and fifteen foot cables with quick connect and disconnect ends. The Batteries had to have a full charge before every day of racing. I carried a thirty amp charger for that, and ran a cable from the Motel Room or an outlet on some post in the parting lot. Sometimes it was a hassle.

I always had a big half inch ratchet lying on the ground by the starter; some times I would have to turn the motor past the compression stroke so the starter would work. It was a lot of trouble to use but it became one of the big attraction at the drags, spectators were sometimes standing around to watch me fire the motors just to see that starter. The NHRA liked it so much that when I did my Exhibitions at the Nationals they had me take every thing right out on the starting line to fire up for the run, while talking about that starter.

Joe Smith - All Rights Reserved

Abonohu te:

Postimet (Atom)